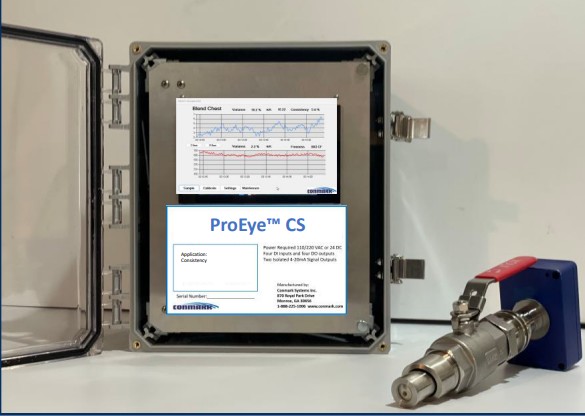

ProEye® CS Consistency Transmitter

A “New” Consistency Measurement that is Easy to Own!

Conmark ProEye® CS resets the bar in consistency measurement and control by using a patented measuring technique to determine the total consistency properties of a pulp mixture. Add Conmark® remote calibration and configuration service combined with intuitive configuration menus, makes the ProEye® unlike any other consistency transmitter on the market today. Troubleshooting and verification testing can be completed remotely by mill personnel or aided by Conmark® Systems. Now individual consistency measurements can be easily managed or can be integrated into a Variability Reduction program to benefit production.

The ProEye® CS measures by continually calculating a matrix of strobed LED responses from the furnish in “real-time“ to provide a consistent reading for use by operations.

ProEye® CS Key Attributes

Setting parameters and calibration is simple. The ProEye® uses advanced mathematical tools to evaluate the samples and calculate correlation, regression, and simulation modeling that is needed to correctly analyze the process consistency. Placing lab sample information into the optional Conmark® Cloud Service allows historical measurement information to be included in the calibration calculations. Improved performance of the measurement loop results. ProEye® uses statistical techniques to evaluate the deviation of the readings from the previous calculations and if warranted automatically adjusts the transmitter settings to the new process conditions. The performance remains on target and performing reliable.

Transmitter has:

One 4-20mA output for Consistency.

Process temperature: +40…+250°F

Wetted Material: AISI316L or Titanium.

Lens: Sapphire lens bonded to metal; no seals.

Consistency Range: 0 to 12%

Power Required: 115 AC 1 amp.

Conmark ProEye® is manufactured in the USA