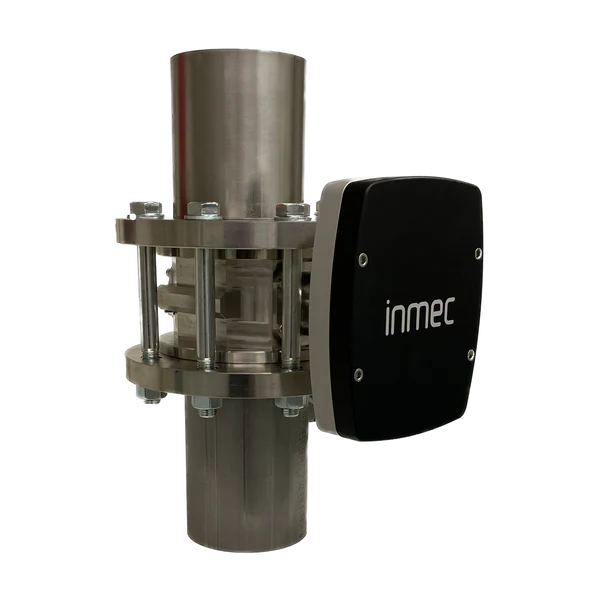

Wet End Charge Analyzer

The Wet End Charge Analyzer gives the ability to optimize wet-end chemistry and control anionic trash. The Charge Analyzer is used as well to quantify the effect of various additives on system charge, providing a useful tool for assessing and improving process efficiency.

Manufactured for easy maintenance and excellent reliability, the online Wet End Charge analyzer is the most proven technology available in this field. The analyzer is suitable for process control as well as an information source. Also, no chemicals are needed for measurement and all the materials have been specially chosen for corrosion resistance.

The Reliable Tool for Full Control

In many paper and pulp mills, the Wet End Charge Analyzer has proven to be a solid tool for controlling both the process and the chemicals at the paper machines. The Analyzer uses multiple measurement points in the stock prep and wet end that help papermakers analyze the sources for anionic trash. The most typical installations in paper mills have been the automatic control of the Wet End Charge Analyzer in the short circulation loop of the paper machine or in the wire pit.

Several wet-end measurements have been successfully used to help optimize additive usage and resolve problems such as deposits or poor runnability. However, few methods exist for monitoring the performance and effectiveness of total wet end conditions and how the condition affects the runnability and number of breaks on the machine.

Minimal variability of the furnish charge (in the white water) is a critical factor to maximize the runnability and produce the best quality paper on any kind of machine. The stability of a paper machine® electrochemistry strongly affects machine drainage, retention, and machine draws. Moreover, the wet end of the machine can be easily upset with increased water system closure and the use of recycled furnish.