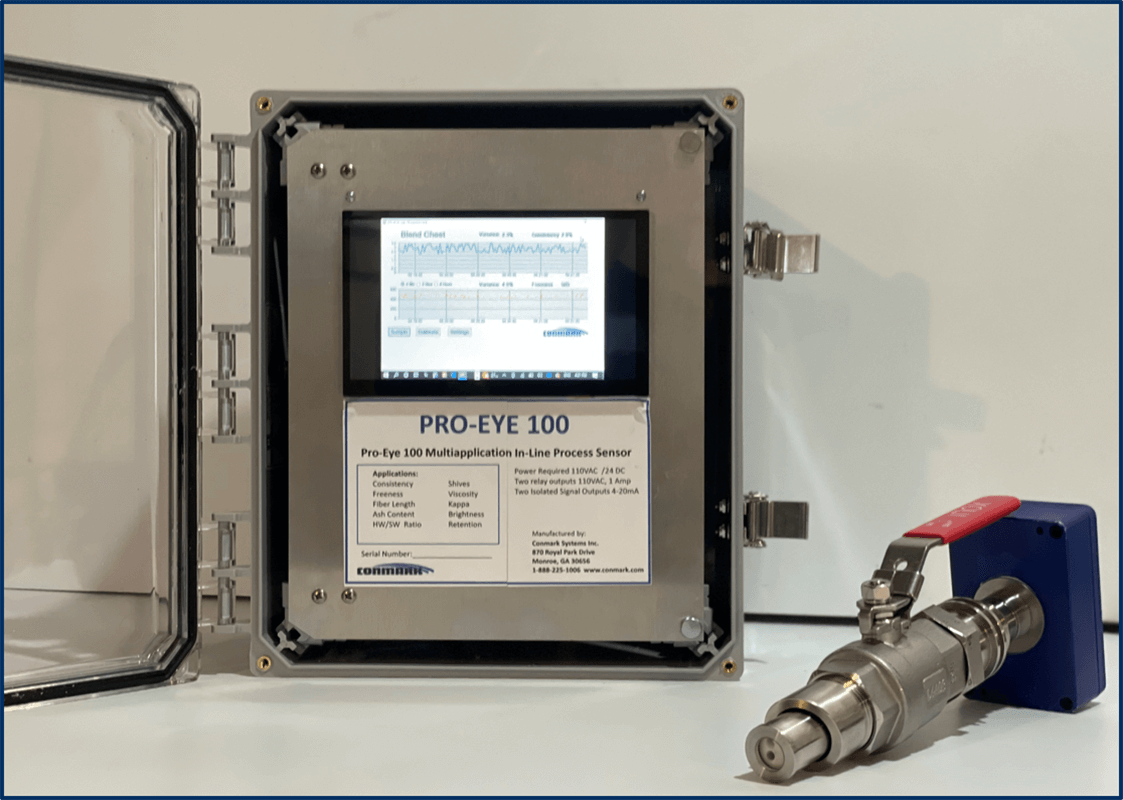

Pro-Eye 100™

Product Information

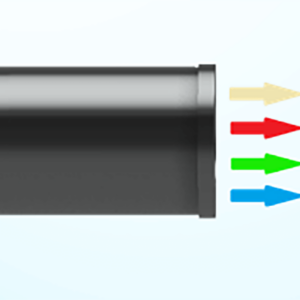

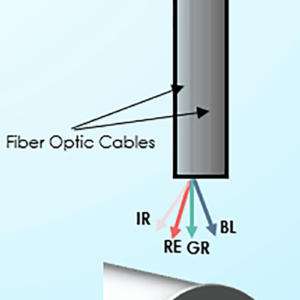

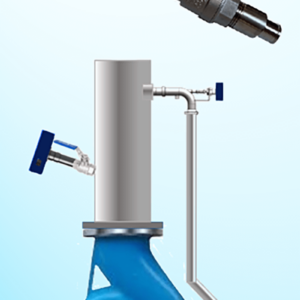

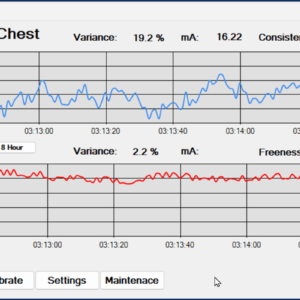

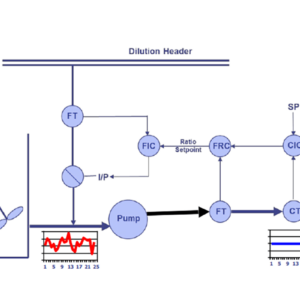

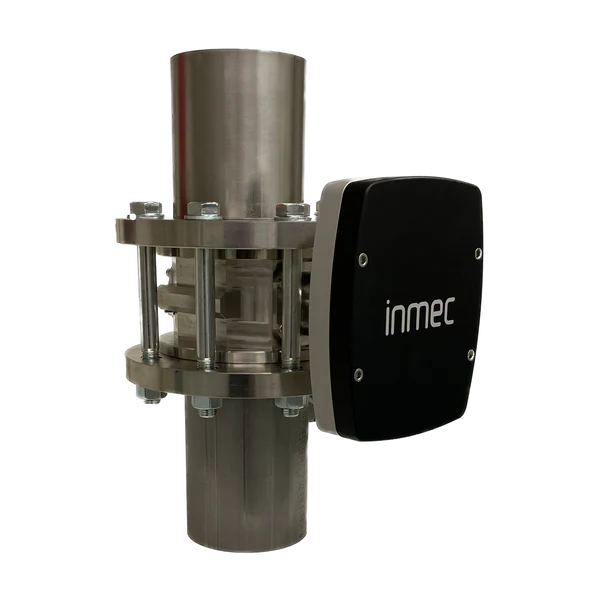

Pro-Eye 100 uses a proprietary measuring technique to determine the properties of the pulp. By calculating a matrix of strobed LED responses from the furnish, the Pro-Eye 100 produces real-time Pulp properties reading for use by operations. Pro-Eye 100 has two independent process variables it can measure simultaneously, like Consistency and Freeness or Ash and Consistency. Typical applications include chemical, mechanical, and recycled pulp and paper machines. The Pro-Eye 100 does not require maintenance. Unlike other online measurement technologies, Pro-Eye 100 provides real-time process measurements for more precise process control. Pro-Eye 100 is manufactured 100% in the USA.

Pro-Eye 100 Applications

The Pro-Eye 100 Remote Display Unit allows the user to choose the applications they want to utilize with the Analyzer from the menu. There are options for Consistency, Freeness, Fiber Length, and Others. The RDU can be installed 45 ft or more from the sensor.

The Display unit has 4 digital inputs, 2 relays, and 2 digital outputs and can be accessed from WI-FI or a Cell connection. Intuitive, menu-driven programming with a 7 color touch screen makes for an easy set-up, calibration, and troubleshooting. The RDU is a Windows 11-based user interface for easy use.

Pro-Eye A cost-effective solution requiring little or no maintenance.

Features of the Pro-Eye100 Process Analyzer:

- 4-20mA two-wire connection. 100mA loop.

- No moving parts, No maintenance.

- Excellent Repeatability, Linearity, and Resolution.

- Automatic Regression-Based calibration.

- Immune to process variations in flow rate, pressure, temperature, and turbulence.

- Wi-Fi or Cell connection anywhere in the world for remote maintenance or startup.